Diving Into the World of Elevators: Typical Issues Encountered by Different Lift Mechanisms

As we navigate with the upright transportation systems of modern-day structures, elevators stand out as an indispensable element of our day-to-day lives. From hydraulic lifts to traction systems and machine-room-less styles, each lift kind comes with its set of typical concerns.

Hydraulic Lifts

Hydraulic elevators, commonly preferred for low-rise buildings, make use of fluid pressure to control the motion of the lift auto (lift repair companies). This mechanism involves a hydraulic pump pushing oil right into a cyndrical tube, creating the elevator to move in the desired direction. While hydraulic lifts are recognized for their smooth and peaceful operation, they do include their very own collection of usual concerns

One widespread trouble with hydraulic lifts is oil leak. The seals in the hydraulic system can wear in time, causing oil infiltration. This not only creates a mess but can also affect the elevator's efficiency if left unaddressed. In addition, concerns with the control system, such as malfunctioning shutoffs or a malfunctioning pump, can create disturbances in the lift's motion.

Normal upkeep and timely repair services are essential to make certain the smooth performance of hydraulic elevators. By attending to these typical issues proactively, structure proprietors can lessen downtime and guarantee the safety and effectiveness of their vertical transport system.

Grip Elevators

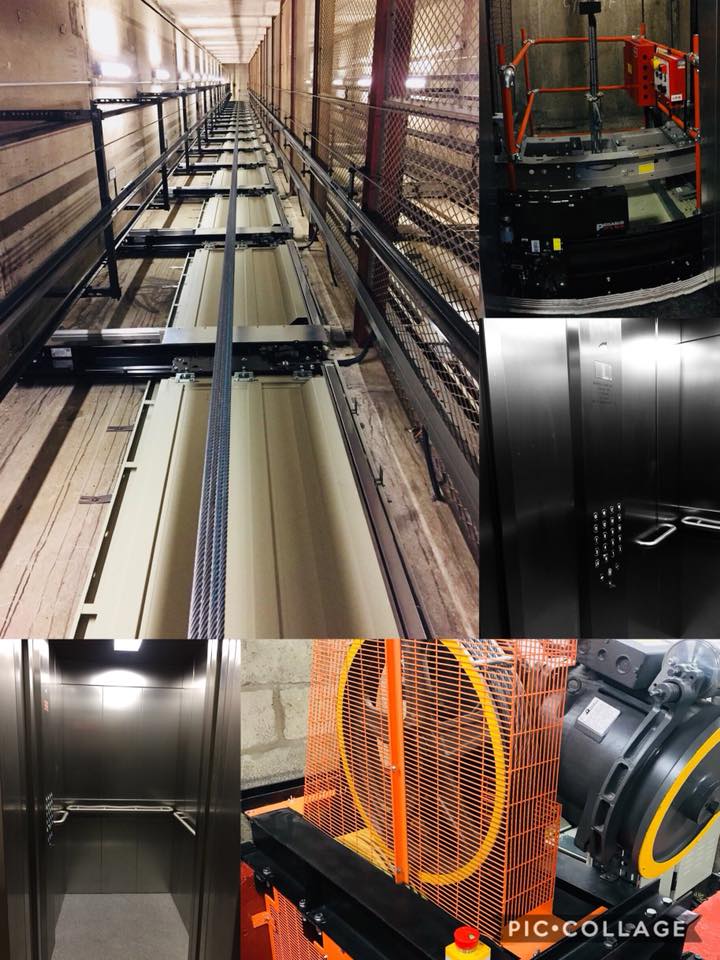

When taking into consideration upright transportation systems in buildings, one more typical kind aside from hydraulic elevators is the grip elevator. Traction lifts operate using a system of ropes and weights that move the lift car by clutching onto the hoist ropes. This mechanism permits smoother and much faster vertical transportation contrasted to hydraulic systems.

One of the typical problems faced by grip elevators is rope wear. The continuous movement of the ropes within the grip system can result in tear and use in time, potentially triggering the lift to malfunction or become hazardous for usage. Routine assessments and maintenance of the ropes are important to make sure the lift's appropriate performance and safety.

An additional problem that traction elevators might experience is associated with the control system. Problems with the control system can cause problems such as erratic motion, hold-ups in reaction times, or also complete shutdowns. Regular screening and upkeep of the control system are vital to stop such problems and ensure the elevator's integrity.

Machine-Room-Less (MRL) Lifts

Among the essential components of MRL lifts is the portable gearless traction device that is installed within the hoistway. This machine efficiently drives the lift vehicle without the need for cumbersome devices found in traditional grip lifts. Furthermore, MRL elevators usually use a counterweight system to stabilize the cars and truck, additional enhancing their power effectiveness.

Regardless of their benefits, MRL lifts might face difficulties associated with upkeep and fixing due to the restricted area for devices setup. Accessibility for servicing elements within the shaft can be restricted, requiring specialized training for professionals. Proper maintenance schedules and routine examinations are vital to make certain the ongoing smooth procedure of MRL elevators.

Overloading and Weight Limit Issues

Straining and weight restriction concerns are critical worries in lift procedures. Elevator find manufacturers design raises with certain weight capabilities to guarantee passenger safety and tools durability.

When elevators are overloaded, it puts too much stress on the motor, cables, and various other elements, potentially causing breakdowns or failures. If they find excess weight, security devices such as sensing units and overload sensors are in place to stop lifts from relocating. Furthermore, going beyond weight limitations can result in raised energy consumption and damage on the lift system.

To mitigate straining problems, building supervisors should plainly display weight limitations in lifts and educate owners on the significance of sticking to these restrictions - lift repair companies. Website Normal upkeep checks by certified professionals can also assist make certain that elevators are running within secure weight specifications. By addressing overloading and weight limitation concerns proactively, building owners can improve lift security and effectiveness

Electric System Failures

Surpassing weight limitations in lifts can not only result in mechanical concerns but additionally possibly contribute to electric system failures within the lift infrastructure. Electrical system failures are a vital problem in lift operation, as they can trigger unanticipated closures, breakdowns, or perhaps security dangers. One usual electric concern is the overheating of components because of extreme present circulation caused by overloading the elevator beyond its capability. This can cause harm to the control, wiring, or motor systems, resulting in costly fixings and downtime.

Furthermore, power surges or variations in the electric supply can likewise interrupt the lift's procedure, influencing its efficiency and security. These electrical disruptions can harm delicate lift components such as control panels, circuit boards, or sensing units, bring about system failures. Regular upkeep and examinations are critical to recognize and deal with possible electrical issues without delay, making sure the safe and reliable operation of elevator systems. By adhering to weight limitations and carrying out regular electrical system checks, structure owners can mitigate the threat of electrical failings in elevators.

Conclusion

Hydraulic elevators, usually liked for low-rise buildings, use fluid pressure to regulate the motion of the lift cars and truck.When thinking about vertical transport systems in buildings, another usual kind aside from hydraulic dig this lifts is the grip elevator. Traction lifts run utilizing a system of ropes and counterweights that relocate the lift auto by grasping onto the hoist ropes. Unlike traditional lifts that need a separate maker space to house the devices, MRL lifts integrate many of the parts within the shaft, eliminating the requirement for a dedicated device area.In conclusion, elevators deal with usual issues such as hydraulic breakdowns, grip system failures, and electric system issues.

Comments on “London Lift Company: Giving Comprehensive Lift Solutions Throughout the Funding”